|

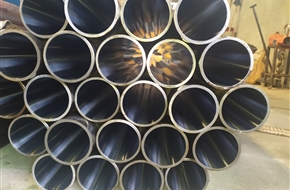

Similar name: honing tube, honed bore tube, smooth bore tube, cylinder tube, skived bore tube, grinding tube Standard: ASTM A519, DIN2391 Grade:ST52,ST52.3,CK45,Q345B,EN355,16Mn,STKM13C,SAE1020/1026/4140,42CrMo,TP304/316 etc. OD metric size: 30 to 2000 mm OD imperial size: 1.5" to 50" (inch) Length: max 20 Meter Straightness: <0.5 mm/m Tolerance OD: DIN 2391 Tolerance ID: ISO H8, H9, H10 Roughness (Ra): <0.8 Application: construction machinery, metallurgical machinery, plastic machinery, mining machinery, road construction machinery, hydraulic and pneumatic cylinders Other request can be discussed. |

Dimension Available:

|

Manufacturing Process |

Tube ID |

Length |

Straightness |

Dimensional Accuracy |

Tolerance on ID |

Inner Bore Roughness |

|

honing |

Φ40-800mm |

≤13m |

0.2-0.3mm |

H8~H9 |

±8% |

≦0.8

um |

Chemical Composition:

|

grade |

C |

Si |

Mn |

P |

S |

Cr |

Ni |

Cu |

V |

Al |

|

1020 |

0.17-0.23 |

0.17-0.37 |

0.35-0.65 |

≦0.035 |

≦0.035 |

≦0.25 |

≦0.30 |

≦0.25 |

- |

- |

|

C45 |

0.42-0.50 |

0.17-0.37 |

0.50-0.80 |

≦0.035 |

≦0.035 |

≦0.25 |

≦0.30 |

≦0.25 |

- |

- |

|

16Mn |

0.13-0.19 |

0.20-0.60 |

1.20-1.60 |

≦0.030 |

≦0.030 |

≦0.030 |

≦0.30 |

≦0.25 |

- |

- |

|

27SiMn |

0.24-0.32 |

1.10-1.40 |

1.10-1.40 |

≦0.035 |

≦0.035 |

≦

0.30 |

≦0.30 |

≦0.20 |

- |

- |

|

ST52 |

≦0.20 |

≦0.50 |

≦1.70 |

≦0.035 |

≦0.035 |

≦0.30 |

≦0.50 |

≦0.30 |

≦0.15 |

- |

|

ST52.3 |

≦0.18 |

≦0.50 |

≦1.70 |

≦0.030 |

≦0.25 |

≦0.30 |

≦0.50 |

≦0.30 |

≦0.15 |

≥0.015 |

Mechanical Property

|

Grade |

Cold finished (hard) (BK) |

Cold finished (hard) (BK+S) |

Hardness |

Impact Value (-20°C) |

|||

|

T.S bN/mm2 |

Elongation 85% |

T.S bN/mm2 |

Y.S SN/mm2 |

Elongation 85% |

|||

|

1020 |

≥550 |

≥8 |

≥520 |

≥400 |

≥15 |

170 |

-- |

|

C45 |

≥680 |

≥5 |

≥630 |

≥520 |

≥12 |

190 |

-- |

|

16Mn |

≥640 |

≥5 |

≥600 |

≥520 |

≥14 |

160 |

-- |

|

27SiMn |

≥780 |

≥5 |

≥700 |

≥580 |

≥10 |

220 |

-- |

|

ST52 |

≥660 |

≥8 |

≥620 |

≥520 |

≥15 |

190 |

-- |

|

ST52.3 |

≥660 |

≥8 |

≥620 |

≥520 |

≥15 |

190 |

≥27 |

Size Tolerance (mm) :

|

ID size |

ID Tolerance |

WT Tolerance |

||||

|

H7 |

H8 |

H9 |

H10 |

H11 |

||

|

30 |

+0.0210 |

+0.0330 |

+0.0520 |

+0.0840 |

+0.1300 |

±5% |

|

>30-50 |

+0.0250 |

+0.0390 |

+0.0620 |

+0.1000 |

+0.1600 |

|

|

>50-80 |

+0.0300 |

+0.0460 |

+0.0740 |

+0.1200 |

+0.1900 |

|

|

>80-120 |

+0.0350 |

+0.0540 |

+0.0870 |

+0.1400 |

+0.2200 |

|

|

>120-180 |

+0.0400 |

+0.0630 |

+0.1000 |

+0.1600 |

+0.2500 |

|

|

>180-250 |

+0.0460 |

+0.072 |

+0.1150 |

+0.1850 |

+0.2900 |

|

|

>250-315 |

+0.0520 |

+0.0810 |

+0.1300 |

+0.2100 |

+0.3200 |

|

|

>315-800 |

+0.0570 |

+0.0890 |

+0.1400 |

+0.2300 |

+0.3600 |

|

Size Tolerance (mm) :

|

OD |

Tolerance |

OD |

Tolerance |

|

≤Φ40 |

±0.15 |

Φ160~200 |

±0.80 |

|

Φ40~60 |

±0.25 |

Φ200~240 |

±1.00 |

|

Φ60~80 |

±0.30 |

Φ240~340 |

±1.50 |

|

Φ80~100 |

±0.40 |

Φ340~440 |

±2.00 |

|

Φ100~160 |

±0.50 |

Φ440~520 |

±2.50 |